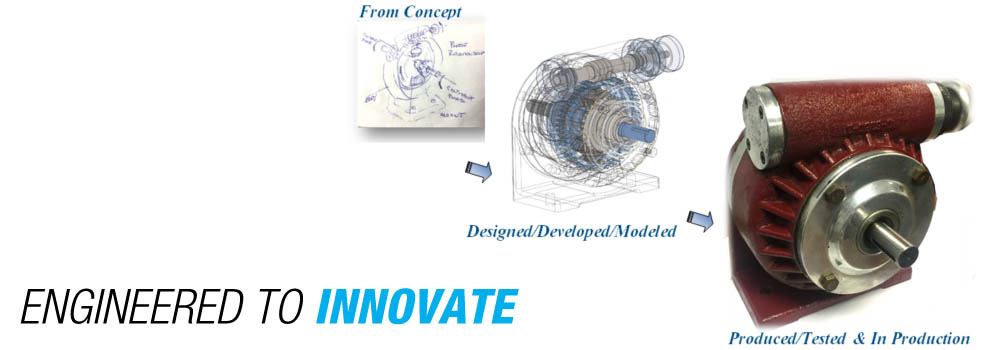

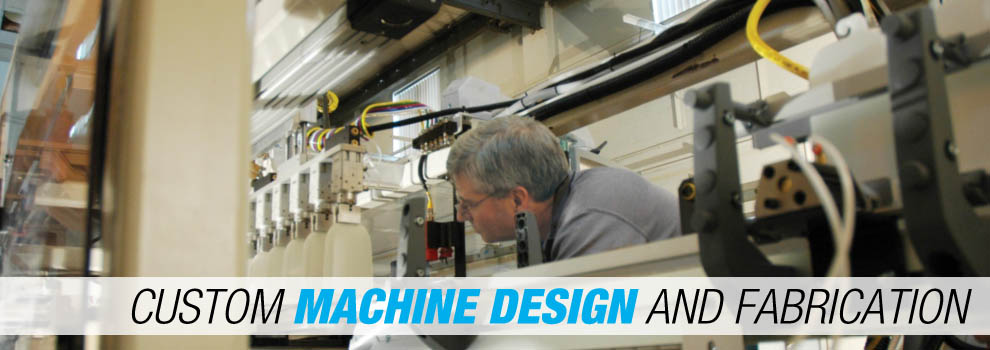

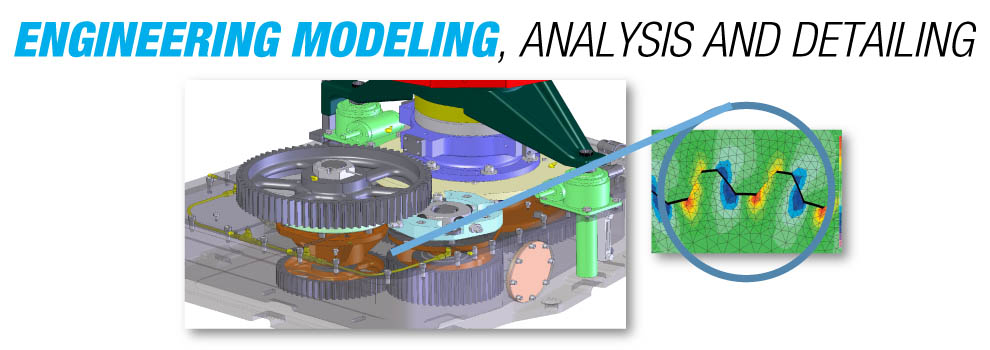

For over 70 years, we have been engineering, designing, and fabricating custom machines. In addition, we have provided engineering modeling, analysis, testing, and data validation for many products. We firmly believe in strong engineering fundamentals. That has been a bedrock approach of any machine we have designed and built or any project we have undertaken.

We have a group of high talented and dedicated mechanical and electrical engineers that collectively represents over 500 years of industry experience. The philosophy of our engineers is simple. Get it done right the first time. Strong engineering background and overwhelming experience has allowed us to innovate products in many industries. It has been observed by many industry experts that our company’s DNA can be seen in many consumer and military products that are used today. Many of the machines we have designed over 50 years ago are still operating. Our clients have a deep understanding of our expertise and the value we bring to their products and processes. We become integrated as a part of our client’s team. Therefore, it is not unusual for us to have a long lasting relationship with our clients for many decades.

Palmer Associates Inc.

Palmer Associates Inc.