Recently, we engineered, built, and/or tested the following custom machines and products for our customers.

[expand title=”Shear and Slit” startwrap=”” endwrap=”” excerpt=” “]

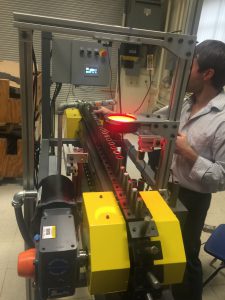

The Slitter/Shear is primarily used on Steel Blanking lines to cut up and remove the tails of coils. The Slitter will cut the strip into set widths and the Shear will cut the strips into set lengths. These smaller pieces can then be deposited into the scrap conveyor underneath of the press.

The Slitter/Shear is located between the exit press uprights. It cuts steel vertically as it drops into a chute going to the scrap conveyor. Its small footprint can fit into any existing Blanking line with minimal modifications. The operation can be automatically programmed to remove the tail at the end of every coil.

Advantages of having a Slitter/Shear:

- Higher scrap value on large tails. Smaller pieces of steel can be put into the scrap conveyor instead of one large piece ran through the stacker and deposited into a tub. Smaller pieces have a larger scrap value than one large piece.

- Less belt damage to runout conveyor and stacker bridge. Bent tails can be the number one reason for cutting belts.

- Less downtime replacing cut belts.

A Slitter/Shear could also be placed in the side chutes of a press to reduce the size of the offal that is being placed into the conveyor. It could be configured into any application where it’s advantageous to have large pieces of steel cut into smaller pieces for ease of handling and higher scrap value.

|

|

|

[/expand]

[expand title=”Robotic Spring Assembly Machine” startwrap=”” endwrap=”” excerpt=”for Automotive application”]

Robotic Spring Assembly Machine was designed to pick the spring plates from a stack, check for correct orientation through a vision system and then place it under the press. Meanwhile, the springs are loaded in the cassette and are shuttled on the spring plate. The robot then grabs the top plate, checks for orientation and places it on top of the spring. The press then comes down on the spring/plate for final assembly. The robot then picks up the entire assembly and places it on the conveyor belt.

This machine was able to:

- Reduce labor cost

- Increase production rate

- Increase part quality

[/expand]

[expand title=”Electrostatic Oiler” startwrap=”” endwrap=”” excerpt=”for applying a very thin film of oil on metal under the brand name ECT (Engineered Coating Technologies) by Palmer”]

http://www.ectbypalmer.com

- Custom design to fit in an existing UAS Oiler envelope(http://www.ectbypalmer.com )

- Used unique ECT blade design that offers largest performance range

[/expand]

[expand title=”Vision system machine” startwrap=”” endwrap=”” excerpt=”to determine defective parts”]

This machine is designed to inspect the correct feature in a tube. When the tube is placed on the moving conveyor, the vision system takes the photo on the moving tube and compares it to the existing feature on file. If the feature does not meet the required dimension, the machine will alert the operator so the bad part can be removed. The purpose of this machine is to eliminate the possibility of sending a wrong part to the client.

|

|

[/expand]

[expand title=”Scrap Tub” startwrap=”” endwrap=”” excerpt=”The Following features were incorporated in the design”]

- Handle large capacity scrap material

- Bottom drop for ease of emptying

- It can be carried by pallet lift or lifted by coil grabbed (see the photo)

- Designed to work with minimum chute length

[/expand]

[expand title=”Thin plastic Material handling machine” startwrap=”” endwrap=”” excerpt=” “]

- Engineered and built to handle very thin (4 mil) plastic material

- The machine will feed, form, and bond the material to make disposable gloves for food industry

- It can be redesign for any other application

[/expand]

[expand title=”Vacuum System” startwrap=”” endwrap=”” excerpt=”for stacking aluminum sheets on a blanking line for automotive Industry”]

- Designed and Built to handle both aluminum and steel sheet on the same line

[/expand]

[expand title=”Rotating scaffolding systems” startwrap=”” endwrap=”” excerpt=”to apply insulating panels to spherical tanks”]

- Application for this system is to install insulation panel to the Liquefied Natural Gas (LNG) tank on the ship.

- Unique to each ship design

- Tight clearance to move around in tight space

- Delivered as a turnkey system

[/expand]

[expand title=”Several Vehicle testing programs completed” startwrap=”” endwrap=”” excerpt=” “]

- Automotive suspension system fatigue testing equipment for load and environment

- Ride evaluation test equipment for automotive on and off road ride analysis

- Class eight truck testing and load response evaluation and design for over the road tankers.

- Fatigue analysis and test development for American with Disability Act (ADA) vehicle. It included test track event design and durability routing

- Vehicle and sub-system test track event design for durability evaluations

- Design and Development for measuring engine component running deflections for new fuel efficient power plant.

[/expand]

Palmer Associates Inc.

Palmer Associates Inc.